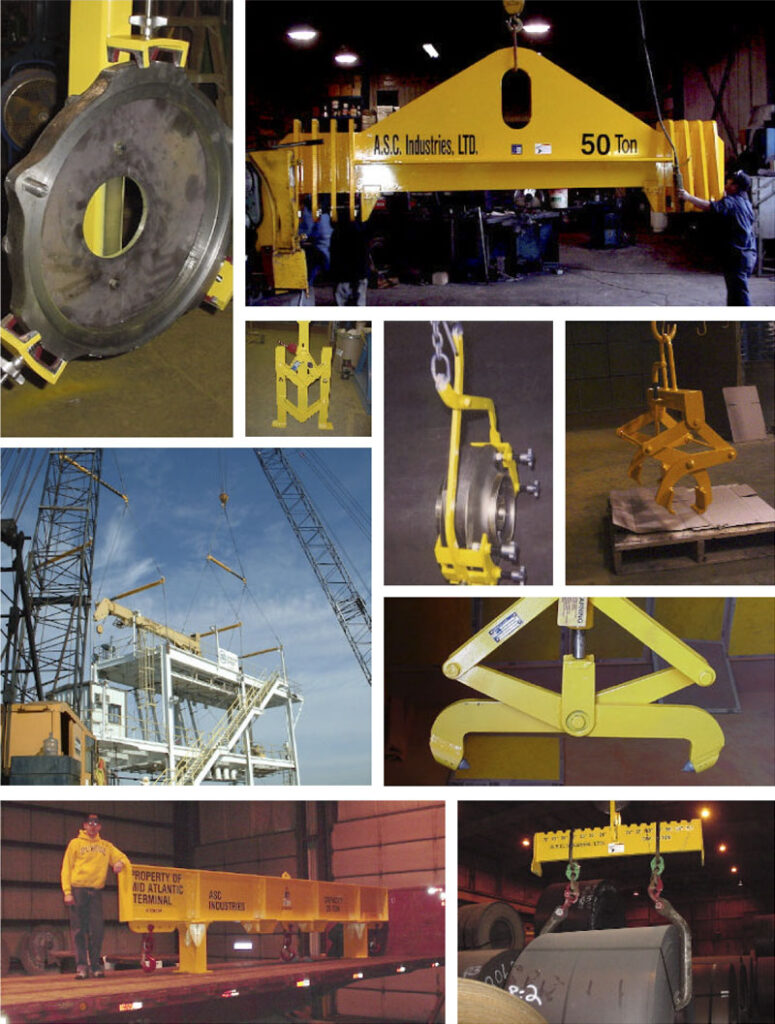

ASC maintains a skilled staff of mechanical engineers to design custom lifting solutions for its clients. Their expertise along with the craftsmanship of experienced welders and fabricators makes ASC the number one choice for high-quality lifting devices.

ASC utilizes Auto Cad software for its design tools and works on an approval drawing basis to ensure customer’s specifications are met. All fabricated lifting devices are manufactured to ASME 30.20 2010 standards. The lifting devices are also proof tested prior to shipment and are designed with a 3 to 1 safety factor.

ASC performs a variety of analysis techniques including: finite element analysis, traditional analysis, calculations and material analysis. ASC can also provide site surveys, reverse engineering, and process development.

All new, modified or repaired structural and mechanical lifting devices require load testing prior to initial use.

All Structural and mechanical lifting devices require the following markings:

All Structural and mechanical lifting devices require inspection by operator or designated person, based on the frequency of use.

All load tests, unless noted otherwise, will be 125% of the rated load.

All modifications to structural and mechanical lifting devices or re-rating shall be by a qualified person or a manufacturer of structural or mechanical lifting devices.

All structural and mechanical lifting devices, manufactured by A.S.C INDUSTRIES. Meets or exceeds ANSI/ASME B30.20 Below-The-Hook Lifting Devices; American National Standards.

All your existing lifting devices can be LOAD TESTED by A.SC INDUSTRIES.

All your future lifting devices can be pre-engineered and specifications established by A.S.C INDUSTRIES Engineering Department.

Email: info@ascindustries.com

Phone: 708-647-4900