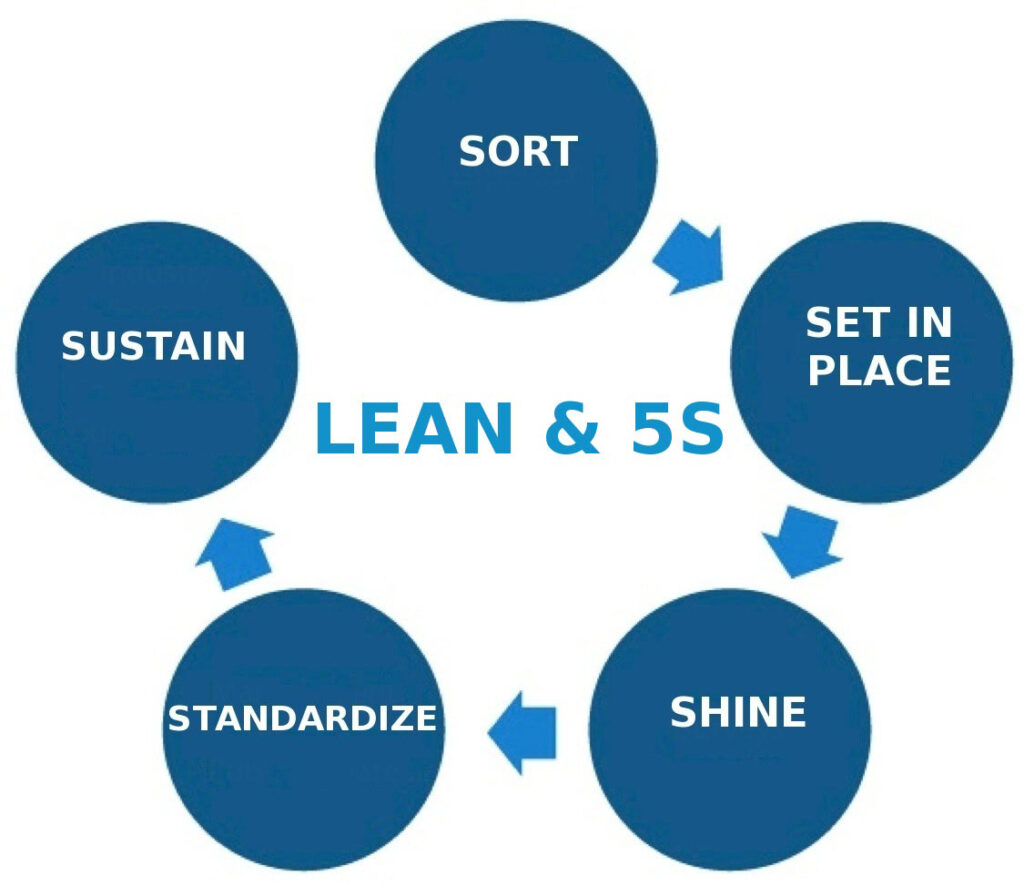

ASC considers 5S and Visual Controls to be the foundation of our Lean Manufacturing systems. 5S and Visual Controls are workplace organizational tools that provide the necessary groundwork for workplace improvement. 5S and Visual Controls ensure that there is a place for everything and that everything is in its place—clean and ready to use.

5S teaches employees to be self-directed and to adopt Lean Manufacturing throughout our facility. 5S and Lean helps establish a team-based corporate culture that empowers the ASC workforce and instills the desire for continuous improvement.

Email: info@ascindustries.com

Phone: 708-647-4900